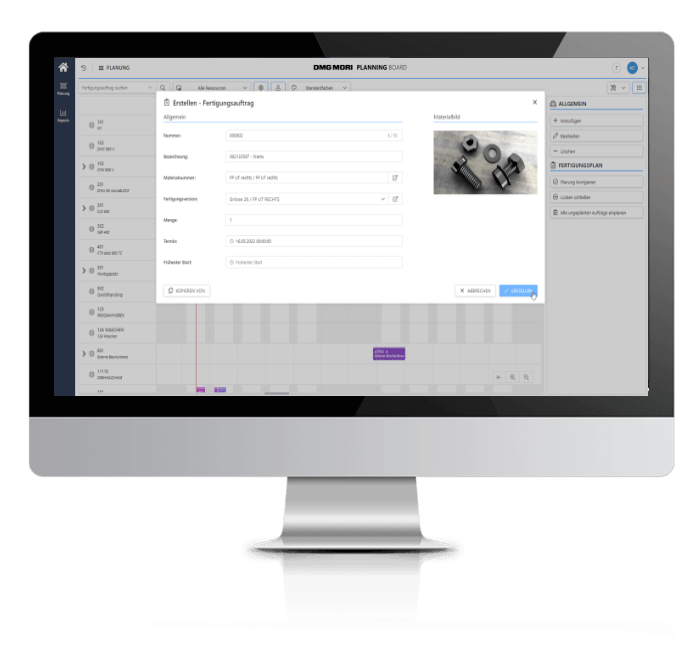

With the PLANNING BOARD we can realistically map our workload & efficiently avoid bottlenecks. After only 10 days, the PLANNING BOARD has completely replaced our planning board.

Joshua Hempel,

Jörg Lintzen GmbH

All production data in your company at a glance at all times: Powerful shop floor data acquisition software makes it possible. Obtain usable data on the current production status and react to changes to flexibly adjust the detailed planning of your resources.

PRODUCTION FEEDBACK, our software for automatic production data acquisition, makes all this possible.

Learn more about our digital production planning

Test our software free of charge and see for yourself.

PRODUCTION FEEDBACK is a core application of PRODUCTION PLANNING & CONTROL. With the PDA software, the status of production orders, their results with consumed times and quantities of produced parts as well as possible malfunctions can be reported back to production planning. Such an analysis of your actual data enables flexible and automatic rescheduling during ongoing production. This increases availability and thus makes your company even more effective.

Automated collection of your production data and - depending on the situation - flexible rescheduling of production: with our PDA software, you can do just that. The application can be combined with our PLANNING BOARD and PRODUCTION PLANNING. Keep an eye on all orders within production. Another plus: incoming orders can be recorded by employees at the machines as well as at other workstations with appropriate access control.

Any malfunctions are reported directly back to the system, an automatic recalculation and an adjustment of the production planning thus take place regularly and automatically, so that the individual operations always remain logically connected. You save capacities and resources, while our PDA software does the work for you.

Flexible production control

Integrated quality assurance

Are you interested in introducing our PDA software PRODUCTION FEEDBACK to digitally support and improve the manufacturing processes in your company? Our staff will be happy to support and advise you individually.

Or do you have questions on topics such as PDA, MDC or MES? Of course, we are always at your side with our network of experienced experts from various areas of Industry 4.0. Please use our contact form for this purpose. We look forward to hearing from you!